Precision Gearbox Mechanical Assembly

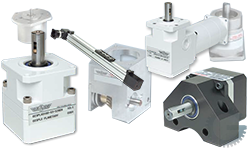

Precision Gearhead, Gearbox & Gearmotor Machining, Assembly & Design

Precision gearbox assembly for engineers by engineers.

Over 40 years of experience allows us to respond creatively and efficiently to your requirements with our engineering, manufacturing and assembly knowledge.

Assembly

Practical know-how and proven assembly techniques enable us to build gearboxes, gearheads and other mechanical assemblies to the most exacting requirements. Most of this work is built up from components that we manufacture, whether to customer specification or to our own rigorous set of standard specifications. With our ability to vertically integrate we can offer cost effective solutions for your assembly requirements. We are specialists in precision gear assemblies, bearing assemblies, motor assemblies and electromagnetic sub-assemblies. We can supply fully tested and vetted assemblies.

Cost-Effective and Proven Gearboxes

With increased subassembly outsourcing, the need for responsive qualified gearbox suppliers has grown significantly. Our 40 years of experience allow us to respond creatively and efficiently to these requirements with our engineering, manufacturing and assembly know-how, integrated with performance testing.

ISO 9001

Quality Management

Quality Control

For over 40 years, quality has driven Gear Suppliers. Today, we incorporate the latest inspection techniques and a continuous improvement program to ensure the quality standards are maintained at the highest levels. We operate under an ISO9001 certified quality management system. Our stringent quality control environment begins at the operator level so that any inconsistencies can be discovered early in the process.

Experience to Meet Your Requirements

We been building to custom gear requirements for over 40 years and we’re still going strong. Time and time again customers continue to bring us application requirements that no other manufacturer can do quickly and inexpensively. We have designed and assembled hundreds of custom gearheads. Many applications include semiconductor, food packaging, military and medical industries. So whether it’s something simple as a special shaft or ratio or something more complex we encourage you to contact us.

Linear Slide

Our gearheads are easily adapted to any of the commercially available linear slide products on the market. All of our inline or right-angle gearheads can be used to help reduce inertia. Our products match up directly to products manufactured by: Intek, Linear Industries, Daedel, Star Linear, THK, NSK, IKO, Warner, Tol-O-Matic, Macron Dynamics and Industrial Devices.

Custom Shaft Options

Our gearheads offer increased design flexibility when built with custom shaft options such as dual-output shaft, hollow shaft and even custom input shafts that allows easy mounting to options like brakes, encoders or safety couplings that are used between the motor and the gearhead.

Aerospace & Medical

We have custom products for the and custom components for surgical hand tools for the medical industry. Companies have relied on us over the years to build non-standard products that meet the stringent requirements of these this very important industry.

Semiconductor & Food Packaging Equipment

We custom design and manufacture gearheads that can be manufactured with special seals and special grease for both the semiconductor and food packaging equipment industries. These gearheads meet various IP ratings and are usually painted white rather than our standard black anodized.

We design and stock single or double shaft gearboxes and gearheads. All gearbox assembly carried out using only the finest high-technology metal and non-metal components. Custom and standard spur offset gearmotors are also available.

Please contact us for our complete facilities list.

Contact us by calling: (408) 472-1525

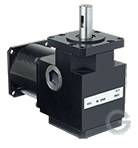

Our planetary gearheads are constructed with a stainless steel output shaft w/ black anodized aircraft aluminum brackets.

Custom and standard gearboxes with solid construction and attention to detail:

- Heat treated steel spiral bevel gears

- Single piece stainless steel output shaft

- Precision tapered roller bearings throughout gearhead

- Front and rear brackets are black anodized aircraft aluminum

- Case hardened steel single piece carrier plate with sun gear

- Viton o-rings at all joints

- Dual-lip nitrile rubber seal with steel core and housing

- Precision case hardened planet gears

- One-piece heat treated stainless steel ring gear housing

- Balanced clamp and high-strength heat-treated steel motor pinion

CUSTOM

GEARBOXES

& SPECIAL PACKAGING

Our 40 years of experience allows us to be able to provide complex precision-machined component parts of high quality that hold tolerances as tight as 2.5 microns. These parts are machined from diverse metals with a variety of hardness, surface treatment, heat-treating and plating requirements.

Contact us by calling: (408) 472-1525

Types of Spur Gearheads:

SPUR GEARHEAD

• High-quality spur gearhead

• Input pinion with balanced clamp collar

• Quick installation

• High reliability design

• High strength steels

• High shaft loading capacity

• Viton O-Rings sealed at each joint

• Sealed ball bearings

• High efficiency design

• All gears are heat treated

• NEMA mounting standards

• 2 year warranty

SINGLE OR DOUBLE SHAFT

SPUR - RIGHT ANGLE

• Tapered roller bearings

• High quality right-angle spur gearbox

• Input pinion with balanced clamp collar

• Quick installation

• High reliability design

• High strength steels

• High shaft loading capacity

• Viton O-Ring sealed at each joint

• Sealed ball bearings

• High efficiency design

• All gears are heat treated

• NEMA mounting standards

• 2 year warranty

SIZES: 017 & 023

RATIOS: 5, 10, 18:1

• One-piece gear cluster

• Cost-effective, light duty spur gearmotor

• Composite bushings throughout gearhead

• Gears are high strength steel and precision hobbed

• Output shaft is heat treated stainless steel

• High temperature, molded composite housing

• Supplied with a 17 or 23 frame step motor

• Standard industry dimensions

• 1 year warranty

Aerotech, Allen-Bradley, Anaheim Automation, Animatics, Applied Motion Products, Baldor, Bodine, CMC Torque Systems, Compumotor, Custom Servo Motors, Dynetic Systems, Eastern Air Devices, Electro-Craft, Emerson, Empire Magnetics, GE Fanuc, Glentek, Globe Motors, Hathaway, Hurst Manufacturing, Indramat, Industrial Devices, Industrial Indexing, Infranor, Inland Motor, Kollmorgen, Lin Engineering, Magmotor, MCG, MFM, Mitsubishi, Moog, MyoStat, Nyden, Oriental Motor, Ormec, Pacific-Scientific, Panasonic, Parvex, Pittman, PMI, QuickSilver, Reliance, Sanyo-Denki, SEM, Siemens, Superior Electric, Tamagawa, Teknic, Vickers, Warner, Yaskawa

Standard and custom precision gearboxes available in many configurations. Many are on the shelf and ready to ship.

We can cross reference Allied Devices, WM Berg, Pic-Design, Stock Drive part numbers.

- catalogs available

Call (408) 472-1525 for expert precision gearbox assembly assistance.